Exceptional Quality – Cost Effective

Gas Turbine Inspection - Field Maintenance & Consulting Services

Contact Us Today to Schedule a Consultation

Exceptional Quality – Cost Effective

Gas Turbine Inspection - Field Maintenance & Consulting Services

Contact Us Today to Schedule a Consultation

Gas Turbine Engine Inspection, Maintenance & Repair Specialists

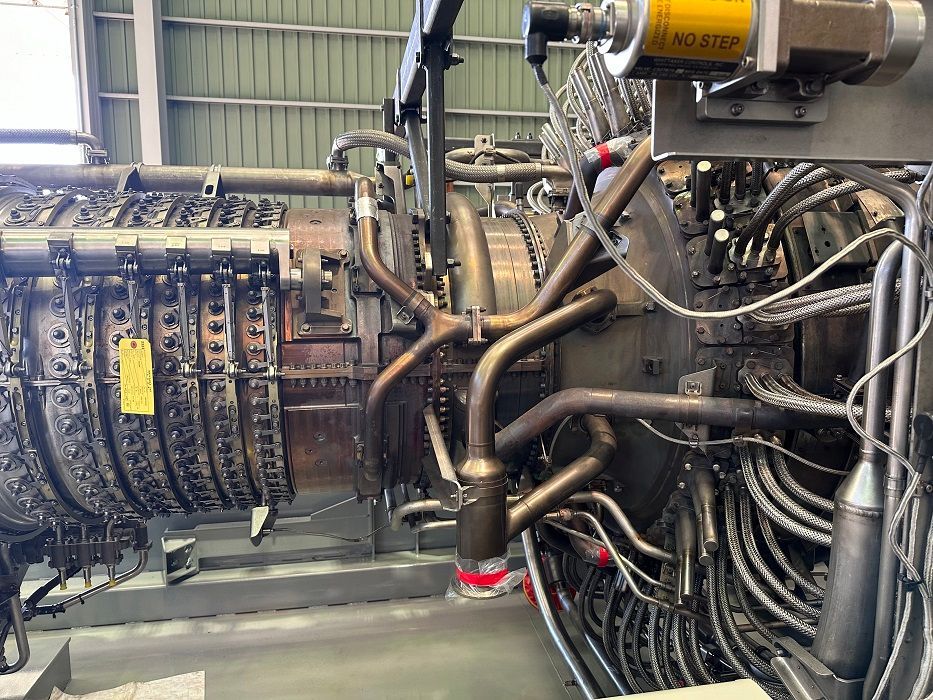

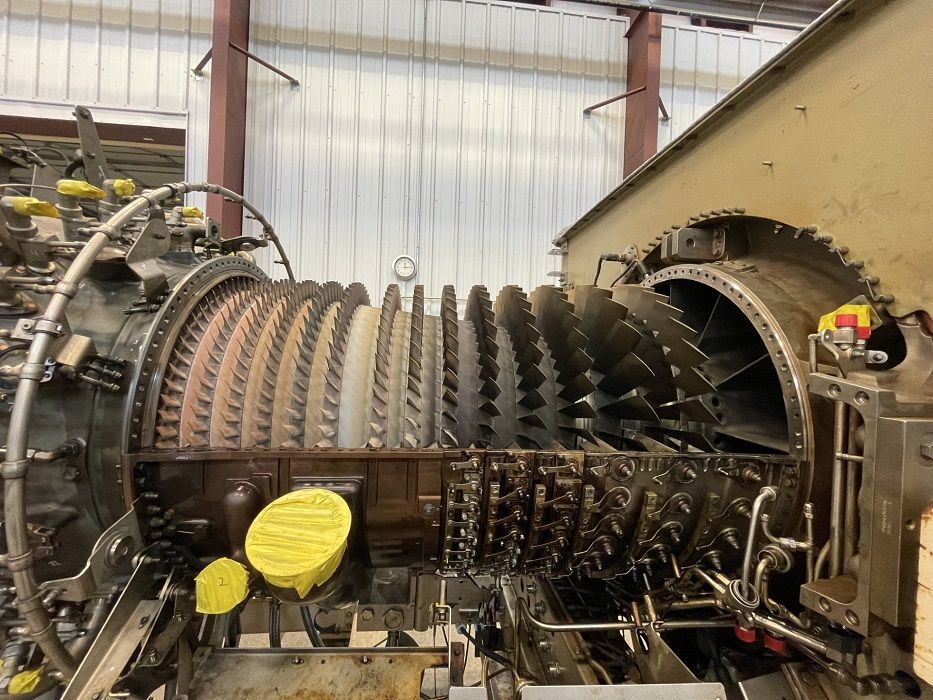

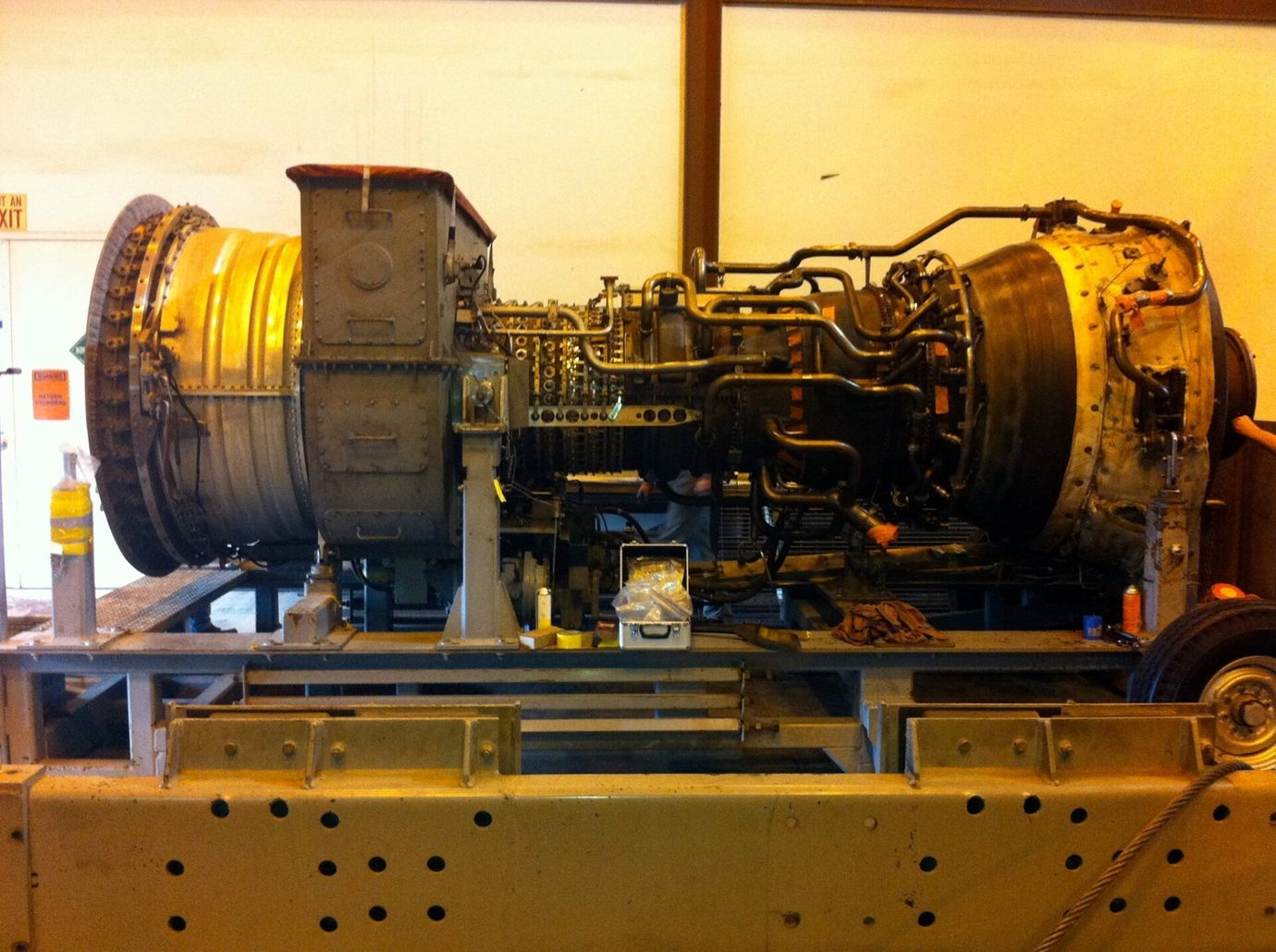

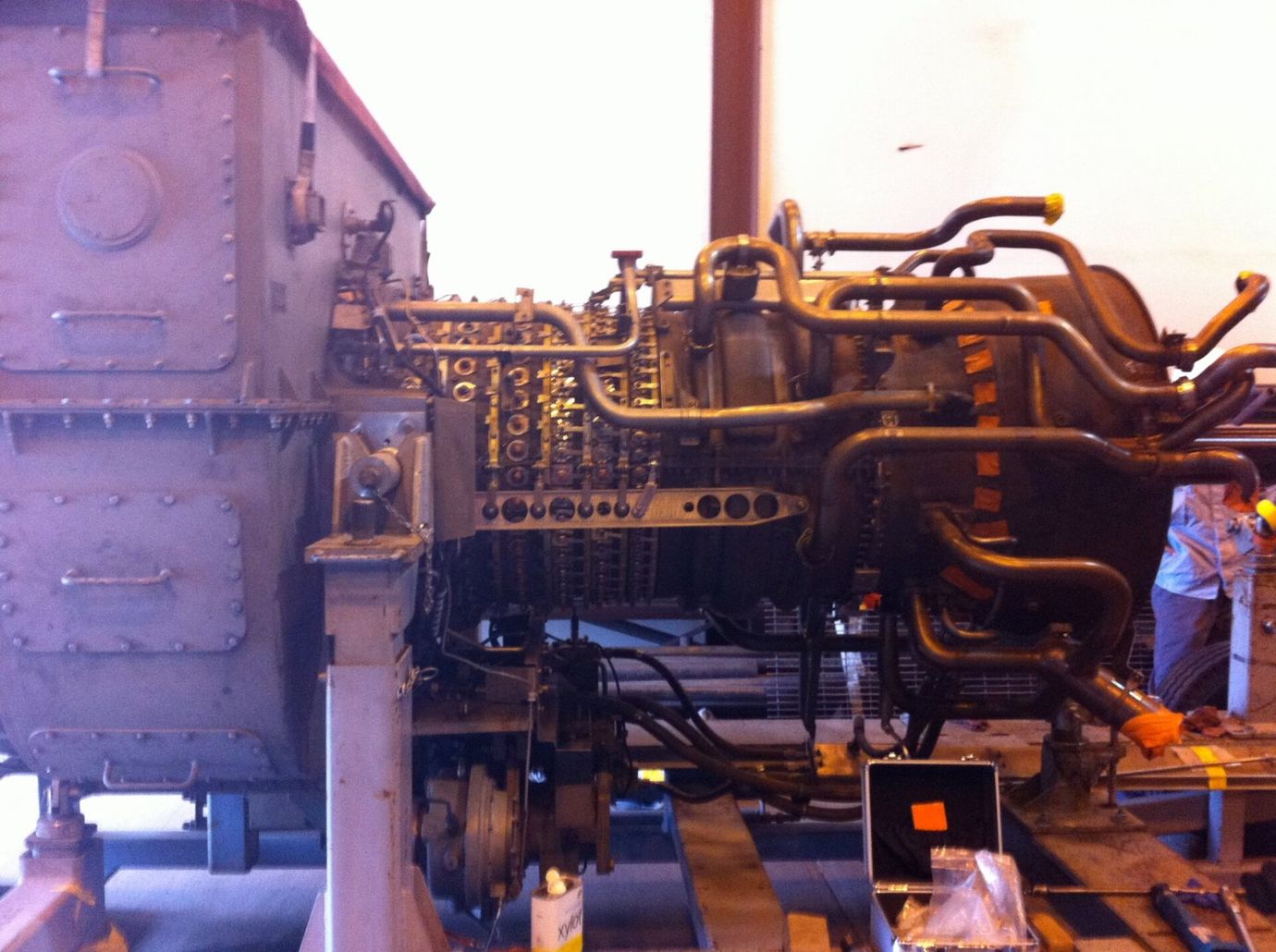

Reed Services Inc is a gas turbine consulting firm specializing in the inspection and scheduled/unscheduled maintenance of aeroderivative gas turbine for the industrial market. We proudly serve industry customers in the United States and in Canada. Our processes and services are specifically focused on you and your needs. You will experience a superior level of service delivered by a very well-trained team of technicians.

We Perform the Following:

Inspection Services

- Borescope Inspections

- Boroblending Scope repairs

- Package Inspections

- Instrumentation Calibrations

Maintenance

- Engine Removal/Install and Alignments

- Hot Section (Field and shop capability)

- VSV Bushing Replacement

- Comply with Service Bulletins/Letters

- VIGV Bushing Replacement and Rigging

- Blade Replacement

Maintenance Consulting

- Operations Training

- Management Training

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

We Perform the Following:

Inspection Services

- Borescope Inspections

- Boroblending Scope repairs

- Package Inspections

- Instrumentation Calibrations

Maintenance

- Engine Removal/Install and Alignments

- Hot Section (Field and shop capability)

- VSV Bushing Replacement

- Comply with Service Bulletins/Letters

- VIGV Bushing Replacement and Rigging

- Blade Replacement

Maintenance Consulting

- Operations Training

- Management Training

We Perform the Following:

Inspection Services

- Borescope Inspections

- Boroblending Scope repairs

- Package Inspections

- Instrumentation Calibrations

Maintenance

- Engine Removal/Install and Alignments

- Hot Section (Field and shop capability)

- VSV Bushing Replacement

- Comply with Service Bulletins/Letters

- VIGV Bushing Replacement and Rigging

- Blade Replacement

Maintenance Consulting

- Operations Training

- Management Training

Our dedication to quality service and on-time maintenance is the reason we have been in this business for so long. Contact us today to schedule a consultation.